As you may know, sustainability is one of our core values at Hippie Snacks, and as a registered B Corporation, we operate on the triple bottom line of people, planet and prosperity. We love the planet and our current line of products are all plant-based, non-GMO, and our ingredients are minimally processed to remain as close as possible to what nature intended.

That sounds pretty cool, but wait – what the heck is up with our multi-laminate (aka soft plastic) packaging?!

Truth be told, we’ve been researching better packaging options for over 10 years. When we did a lifecycle analysis on our company and products, we found out that packaging only accounted for 2% of our overall footprint (check out our Sustainafoodability video for more info). The vast majority of our environmental impact comes from how our ingredients are grown and transported, so we focus our efforts there first to make the biggest difference. To date, we‘ve reduced our carbon footprint from our baseline year (2012) by 45%, which is enough to power 2268 homes with electricity for a year!

But hey, we’re not here to toot our own horn – we came here to talk about packaging.

Because our snacks are made with real ingredients (think whole heads of cauliflower, real avocados, almonds with their skins on!), they require high oxygen, moisture and UV barriers to ensure they arrive to customers fresh. We currently use a combination of different materials and layers like polyethylene terephthalate (PET), aluminum, and linear low-density polyethylene (LLDPE) to keep your snacks fresh longer. We opted not to use in-package desiccants like silica packets because:

- Customers don’t like seeing them in the bag, and we don’t blame you! Everything in a pouch of Hippie Snacks should not just be edible, but delicious.

- Our values don’t align with those of the main manufacturers of food grade desiccant packages.

But even with our current multi-laminate packaging, we have had occasional issues with our real food Avocado Crisps. We do everything in our power to avoid and prevent food waste, because wasted food means that all the energy and resources that went into that product – growing, transporting, making, and shipping – also goes to waste. As firm believers in “waste not, want not,” that’s a tough pill to swallow for us.

In recent years, there have been some really cool advances in materials as well as way more push from our customers to come up with better packaging alternatives. We get it – you care about the products you put into your body and how much waste you put out into the world, and so do we. That’s why we’ve been researching and investing in exploring innovative packaging solutions for the past few years and trying to find a new, better option. Here’s what we’ve looked into so far:

1. Biodegradable

This is a bit of a misunderstood term, so let’s break it down (you’ll see why that’s a great pun in a few seconds). All “biodegradable” means is that a material will break down (degrade) into tiny pieces in the environment (biosphere). Most people are aware of the massive implications that we are facing as a result of microplastics, or biodegradable plastics breaking down into tiny (but still plastic) fragments that seep into our oceans, soils, and food chain. While biodegradable is a step in the right direction from conventional, there are much bigger steps we could take.

2. Compostable

Compostable plastics are defined as materials that will break down under particular circumstances (e.g., high heat, oxygen, moisture) into products that are non-toxic and cause no negative impacts on the environment. The end of life of these materials sounds great but they don’t meet our barrier requirements – yet, which means they haven’t been proven to keep UV, light or oxygen from leaking into packaging enough to maintain the freshness and integrity of our products. We keep checking back in with this industry hoping that there’ll soon be something durable enough for products that have to be shipped and maintain longer shelf lives.

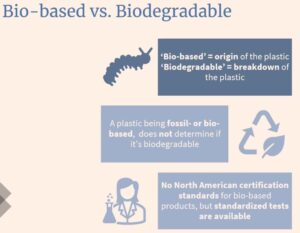

3. Bio-Based

There are also bio-based plastics, which are plastics that have been created from plant or biological materials other than petrochemicals. They are identical to petrochemical plastics except in their source materials. However, bio-based plastic actually creates higher greenhouse gas emissions overall because there are more steps required to convert raw materials into usable bio-based plastic vs. in petroleum refining (used for jet fuel, car fuel, and conventional plastic). This is partly because there isn’t currently a robust supply chain for bio-based plastics, while traditional plastic production is a well-oiled machine, no pun intended. Until we (meaning all of us Earthlings) build out a bio-based plastic infrastructure, it will cost more. There are many who say it just won’t happen unless regulators create incentives for businesses to choose it as well.

4. Recyclable

Now, we also have ‘recyclable’ plastics. The BCEPR program (EPR – extended producer responsibility) tries to create separate waste streams for all the different types of plastic, but we don’t currently have recycling facilities that can actually sort and process all the types of plastic. Flexible, soft plastics such as the ones typically used in food packaging is particularly pervasive, but not easily recycled. Although Recycle BC has started collecting these and there is research being done on how to utilize these materials, there are only a few options as of today.

5. Loop redesign

We’ve also looked into participating in a total packaging redesign and circular economy collection service called Loop that recently launched in Ontario in partnership with Loblaws. Services like these provide products in reusable containers, which are collected by Loop once the product is used up, brought back to a Loop facility to be cleaned, then are filled and used again and again. However, this service requires some costly changes in production processes and of course, packaging. Once they expand into Western Canada, we will evaluate this option again.

6. TerraCycle

Our final current solution is using a service like TerraCycle, whose mission is to recycle the unrecyclable. TerraCycle has dedicated facilities in North America specifically to process and recycle materials that aren’t currently accepted into our municipal recycling streams, like flexible and soft plastics – woohoo! Thanks to our friends over at SPUD, who’ve been working with them for a while, later this year Hippie Snacks packaging will be accepted into their TerraCycle recycling program!

We know this is just the tip of our waste iceberg, but in keeping with our value of transparency, we wanted to share our sustainability journey so you know that we have heard you; we do care and we will find a solution. We want to make sure it is a real, lasting, and effective solution. Thanks for reading along and stay tuned for more developments soon!